Products

Overview:

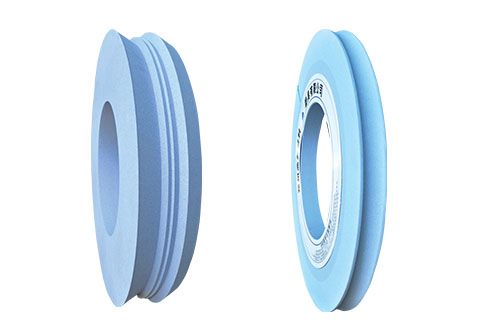

Conventional abrasive including white corundum (WA), brown corundum(A), single crystal Corundum (SA), chrome corundum (PA), green silicon carbide (GC), black silicon carbide (C) and SG abrasive etc. Currently we are able to produce dimensions in the range ofφ1.5mm-φ1600mm grinding wheels. These wheels mainly used to produce wheels for: grinding crankshaft, grinding camshaft. grinding ball, grinding roll, grinding bearing and forming grinding. Types including grinding disc series, strength grinding wheel series, miniature grinding wheel series and etc.

Conventional abrasive including white corundum (WA), brown corundum(A), single crystal Corundum (SA), chrome corundum (PA), green silicon carbide (GC), black silicon carbide (C) and SG abrasive etc. Currently we are able to produce dimensions in the range ofφ1.5mm-φ1600mm grinding wheels. These wheels mainly used to produce wheels for: grinding crankshaft, grinding camshaft, grinding ball, grinding roll, grinding bearing and forming grinding. Types including grinding disc series, strength grinding wheel series, miniature grinding wheel series and etc. Bonds type including high/low temperature ceramic, SG special ceramic, resin bond and etc. The diversity of our products can satisfy different grinding demands.

Compared to traditional grinding process, our grinding wheels’ performance excelled in aspects such as grinding efficiency, length of grinding life as well as appropriate surface roughness. We designed the right grain size to reach appropriate hardness based on different producing technique in order to perfectly match cutting requirements of customers and prevent from cracking in the process of grinding as well.

Good shape retention. High porosity features lower risk of grinding burn. Thus, enabling better ground workpiece profile.

Mainly used for complex profile contour forming grinding.

| Item | O.D. (mm) | Tallness(mm) | I.D. (mm) | Handle/shaft/metal base |

| DIM. | Φ≥1.5 | T≥1.0 | H≥0.8 | As needed |

| Remark | Available for complex profile | Working part tallness | Refers to I.D. of steel base or grinding wheel. | Steel/Aluminum/Alloy/Cemented Carbide |

If you have any questions, please leave us a message, we will serve you warmly!

We have accumulated a wealth of practical experience and can provide you with professional product solutions. The project manager will provide you with product information, quotations, preferential policies, etc.

Free design proposal