Products

Overview:

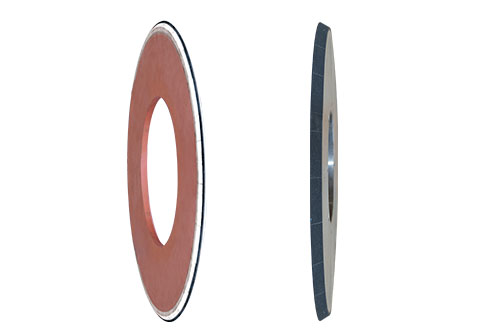

Compared to traditional grinding process, our grinding wheels’ performance excelled in aspects such as grinding efficiency, length of grinding life as well as appropriate surface roughness. We designed the right grain size to reach appropriate hardness based on different producing technique in order to perfectly match cutting requirements of customers and prevent from cracking in the process of grinding as well.

Compared to traditional grinding process, our grinding wheels’ performance excelled in aspects such as grinding efficiency, length of grinding life as well as appropriate surface roughness. We designed the right grain size to reach appropriate hardness based on different producing technique in order to perfectly match cutting requirements of customers and prevent from cracking in the process of grinding as well.

Higher operating speed and grinding efficiency.

Longer grinding life and less dressing frequency needed.

Great improve in profile contour retention.

Gear profile grinding, thread grinding, slot and profile grinding, axial positioning of shoulder or end-face grinding.

| Item | O.D. (mm) | Tallness(mm) | I.D. (mm) | Handle/shaft/metal base |

| DIM. | Φ≥1.5 | T≥1.0 | H≥0.8 | As needed |

| Remark | Available for complex profile | Working part tallness | Refers to I.D. of steel base or grinding wheel. | Steel/Aluminum/Alloy/Cemented Carbide |

If you have any questions, please leave us a message, we will serve you warmly!

We have accumulated a wealth of practical experience and can provide you with professional product solutions. The project manager will provide you with product information, quotations, preferential policies, etc.

Free design proposal