Products

Overview:

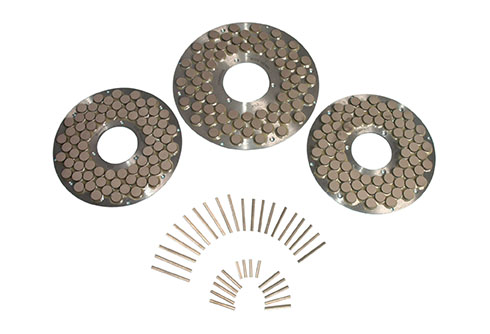

Electroplated grinding wheel can be categorized into Electroplated diamond grinding wheel and Electroplated CBN grinding wheel. Electroplated diamond grinding wheel has widely applications including form processing of glass,magnetic material,hard alloy,ceramics and gemstone’s grooving,beveling and edging.

Electroplated CBN grinding wheel mainly used in forming grinding of all sorts of steel, such as grooving and processing many different complex shapes as customer’s requirements.

Compared to traditional grinding process, our grinding wheels’ performance excelled in aspects such as grinding efficiency, length of grinding life as well as appropriate surface roughness. We designed the right grain size to reach appropriate hardness based on different producing technique in order to perfectly match cutting requirements of customers and prevent from cracking in the process of grinding as well.

Higher material removal rate with longer service life. Lower dimensional tolerance for ground workpiece. Be able to maintain stable dimensional tolerance so it is quite suitable for automatic production processing on CNC machine.

Especially suitable for precision processing of cast iron, powder metallurgy artifacts, ceramic materials and other hard brittle materials.

| Item | O.D. (mm) | Tallness(mm) | I.D. (mm) | Handle/shaft/metal base |

| DIM. | Φ≥1.5 | T≥1.0 | H≥0.8 | As needed |

| Remark | Available for complex profile | Working part tallness | Refers to I.D. of steel base or grinding wheel. | Steel/Aluminum/Alloy/Cemented Carbide |

If you have any questions, please leave us a message, we will serve you warmly!

We have accumulated a wealth of practical experience and can provide you with professional product solutions. The project manager will provide you with product information, quotations, preferential policies, etc.

Free design proposal